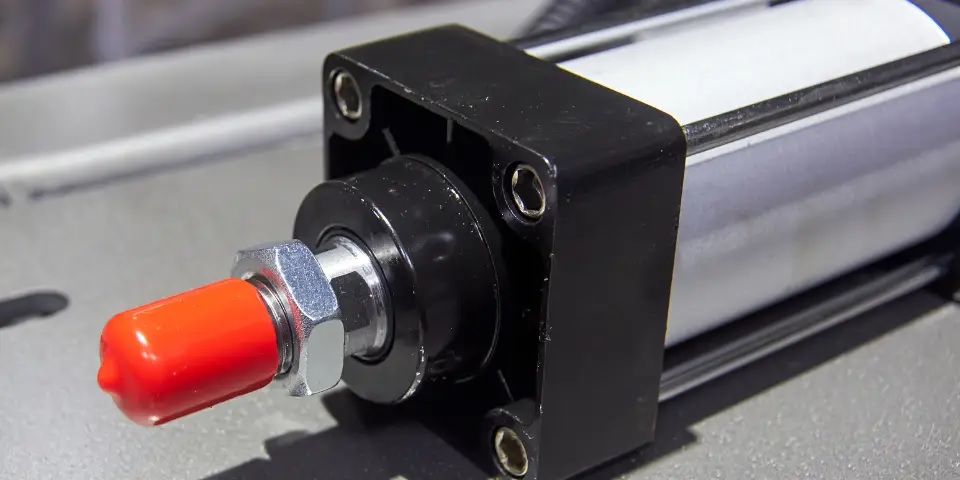

Training in pneumatic system management is crucial for ensuring the safe, efficient, and reliable operation of these systems, which are widely used in various industries, including manufacturing, automotive, and robotics. Pneumatic systems utilize compressed air to transmit and control energy, making them vital for powering machinery, tools, and automation processes. The significance of training in this field cannot be overstated, as it directly impacts productivity, safety, and operational costs. One of the primary reasons for emphasizing training in pneumatic system management is safety. Pneumatic systems operate under high pressure, which can pose serious risks if not managed correctly. Without adequate training, personnel may not fully understand the operational limits of the equipment, leading to potential accidents, equipment failures, or even catastrophic incidents. Training programs equip employees with essential knowledge about the components of pneumatic systems, such as compressors, valves, actuators, and filters. Understanding how these components interact helps prevent mishandling that could lead to dangerous situations.

For instance, a lack of knowledge regarding pressure settings can result in over-pressurization, causing equipment rupture or injury to operators. Furthermore, proper training enhances the efficiency of pneumatig systems. Employees trained in best practices for system operation and maintenance are better equipped to identify inefficiencies and potential problems before they escalate. They learn how to conduct routine inspections, diagnose issues, and perform preventive maintenance. This proactive approach minimizes downtime and enhances productivity by ensuring that pneumatic systems operate at peak performance. By understanding the principles of fluid dynamics and system design, they can implement adjustments that lead to energy savings and reduced costs. Moreover, training fosters a culture of continuous improvement within an organization. When employees are encouraged to pursue further education and skill development, it creates an environment where innovation and efficiency are prioritized. Trained personnel are more likely to stay informed about the latest technologies and advancements in pneumatic systems, enabling companies to adopt new solutions that enhance performance.

This commitment to training not only benefits the organization but also contributes to employee satisfaction and retention, as individuals feel valued and empowered to contribute to their company’s success. In addition to technical skills, training in pneumatic system management also addresses the importance of teamwork and communication. Effective operation of pneumatic cylinders manufacturer systems often requires collaboration between various departments, including engineering, maintenance, and production. Training programs that emphasize communication skills ensure that team members can work together seamlessly to troubleshoot problems and implement solutions. This synergy is critical in environments where downtime can have significant financial repercussions. Lastly, regulatory compliance is another essential aspect of pneumatic system management that training addresses. Many industries have strict regulations governing the use of pneumatic systems to ensure workplace safety and environmental protection. Training helps employees understand and adhere to these regulations, reducing the risk of legal issues and penalties. By fostering a culture of compliance, organizations can safeguard their reputation and ensure long-term sustainability.